Standard Specification of Nuts

| Nut size | Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes |

|---|---|

| Nuts Length | 3 mm to 200 mm |

| Nut | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard of Nuts | DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts |

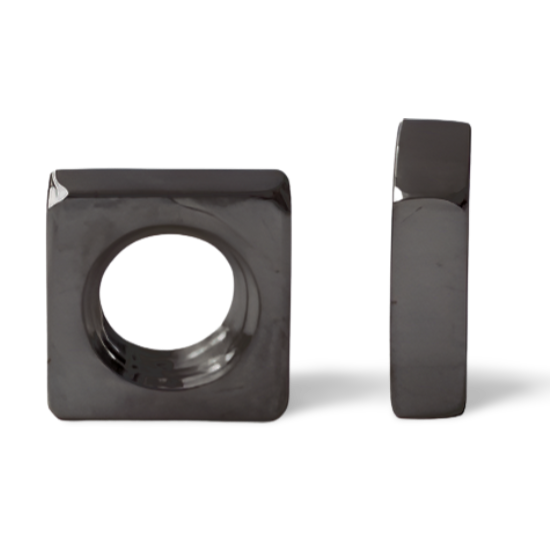

| Form of Nuts | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

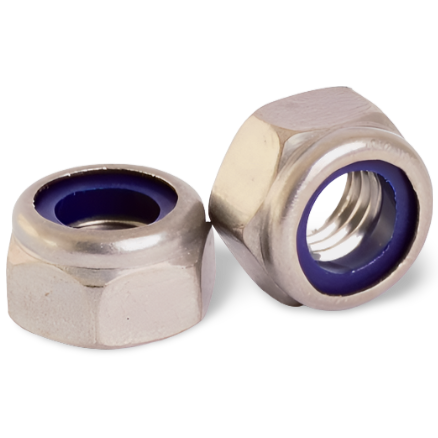

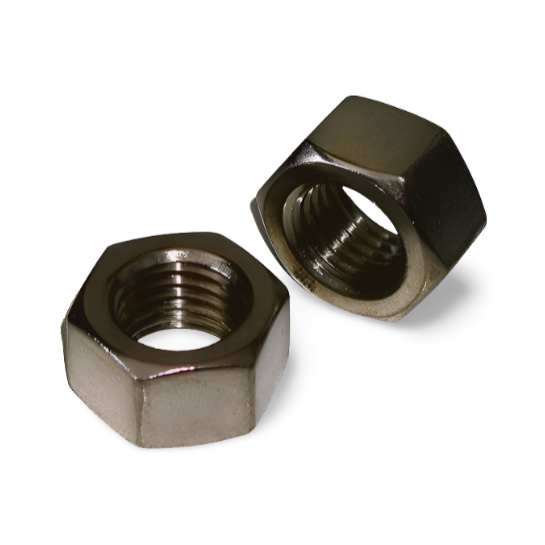

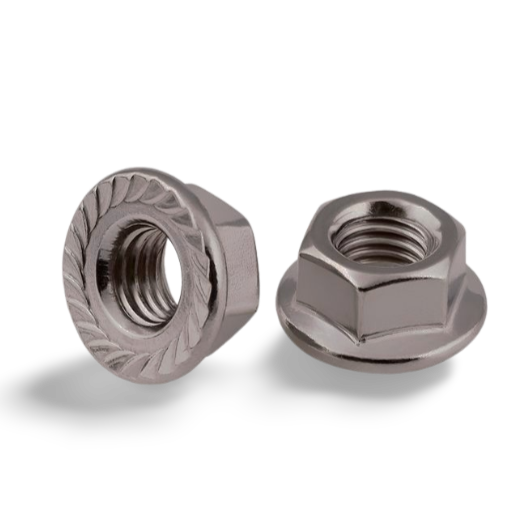

| Popular Types of Nut | Hex Head Nut, Eye Nut, Dome Nut, Wing Nut, T Nut, Panel Nut, Lock Nut, Coupling Nut, Square Nut, Acorn Nut etc. |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate of Nuts | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Production process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive of Nuts | Six-Lobe,Phillips,Phillips/Slot, Slotted etc |

| Packing of Nuts | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating | Ptfe Coated Nuts Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| Nuts finishing | Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide, |