Standard Specification of Screws

| Screw size | Imperial Size: 3/8 to 8″, Metric Size: M10 to M100 |

|---|---|

| Screws Length | 3 mm to 200 mm |

| Screw | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard of Screws | DIN 84, DIN 85, DIN 912, DIN 916, DIN 931, DIN 933, DIN 960, DIN 961, DIN 963, DIN 964, DIN 965, DIN 966, DIN 6912, DIN 6921, ASME B18.2.1, ASME B18.3, ASME B18.6.2, ASME B18.6.3, ASME B18.6.4, ASME B18.7 |

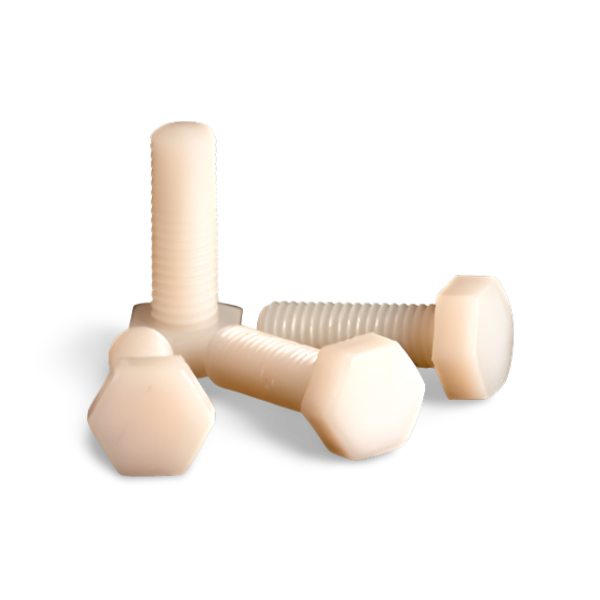

| Form of Screws | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Popular Types of Screw | Hex Head Cap Screws, Socket Set Screws, Anchor Screws, Blind Rivet, Socket Head Screws, Concrete Screws, Shoulder Screws, Panel Screws, Threaded Screws, Machine Screws etc. |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate of Screws | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production process | M24-M100: hot forging, M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive of Screws | Six-Lobe,Phillips,Phillips/Slot, Slotted etc |

| Packing of Screws | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating | Ptfe Coated Screws Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| Screws finishing | Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide |