Standard Specification of Washers

| Washer | Specifications |

|---|---|

| Size | Imperial Size: 3/8 to 8″, Metric Size: M10 to M100 |

| Length | 3 mm to 200 mm |

| Standards | DIN 84, DIN 85, DIN 912, DIN 916, DIN 931, DIN 933, DIN 960, DIN 961, DIN 963, DIN 964, DIN 965, DIN 966, DIN 6912, DIN 6921, ASME B18.2.1, ASME B18.3, ASME B18.6.2, ASME B18.6.3, ASME B18.6.4, ASME B18.7 |

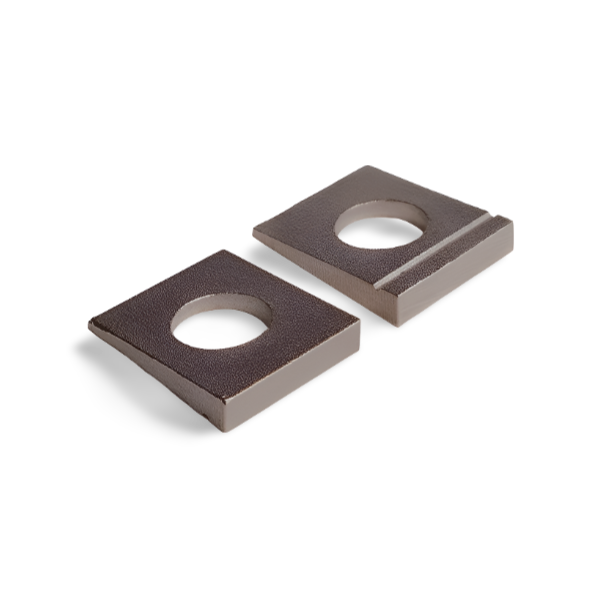

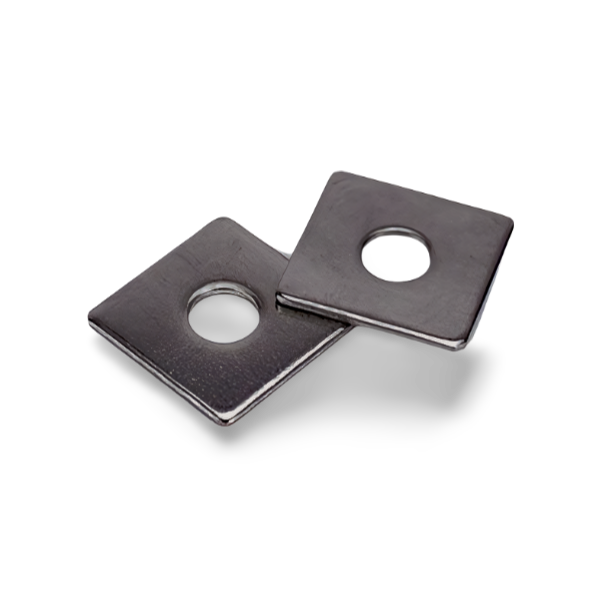

| Forms | Hex, Threading, Square, Round as per Gauge Etc. |

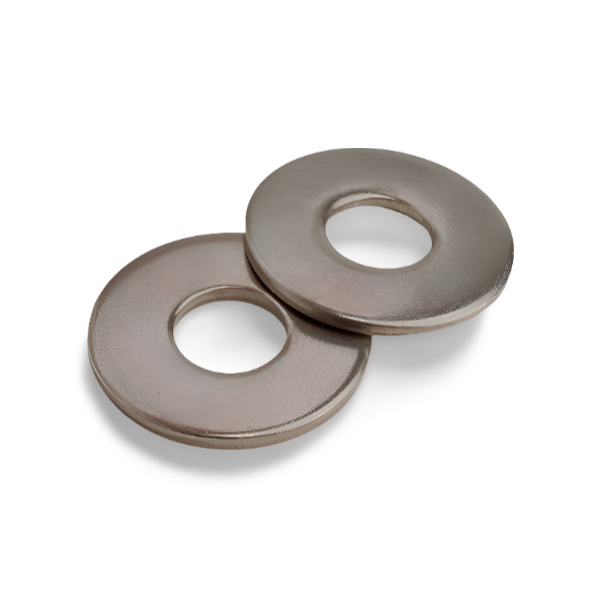

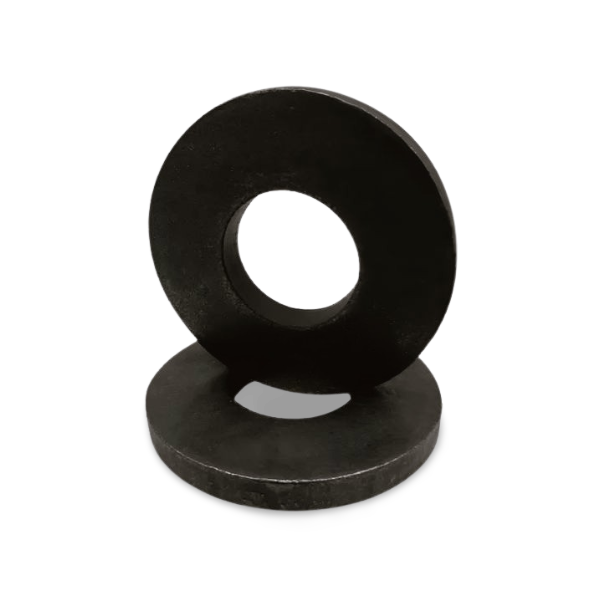

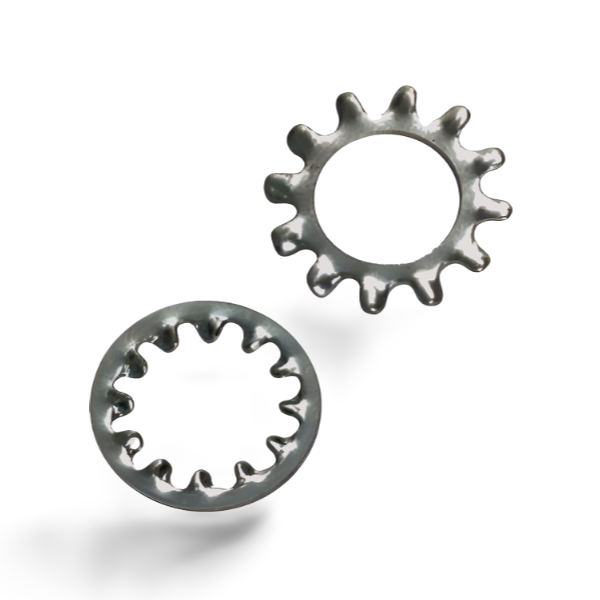

| Types | Structural Washer, Belleville Washer, Countersunk Washer, Fender Washer, Flat Washer, Sealing Washer, Slotted Washer, Spherical Washer, Split Lock washer, Tooth Lock washer, Wave washer, Torque Washer |

| Head drive | Six-Lobe,Phillips,Phillips/Slot, Slotted etc |

| Surface Coating | Ptfe Coated Washers, Phosphate Coating, Teflon Coating, Zinc Coating, Hot Dipped Galvanizing Coating, Cadmium Coating, Xylon Coating |

| Washer finishing | Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide |